Factory Commander® is the world’s leading Cost and Resource Evaluation software platform. With a rapidly growing international installed base, Factory Commander ® has captured the attention of diverse manufacturing, assembly, service, and research organizations. An impressive customer list includes world leaders such as: Hitachi, Hewlett-Packard, Dow Corning, California Institute of Technology, and Sandia National Laboratories. With its proven track record, Factory Commander® is ready to address your critical business applications.

Capacity Planning

For most manufacturing and assembly facilities, the need for additional production equipment must be identified and ordered far in advance of its actual use. If product mix is highly predictable, or if all products use each piece of production equipment equally, an overall production forecast is all that is needed to determine equipment requirements. However, when one product loads a tool to a greater degree than another product, any deviation from the expected product mix can leave the facility with insufficient capacity, even if total production volume is right on forecast.

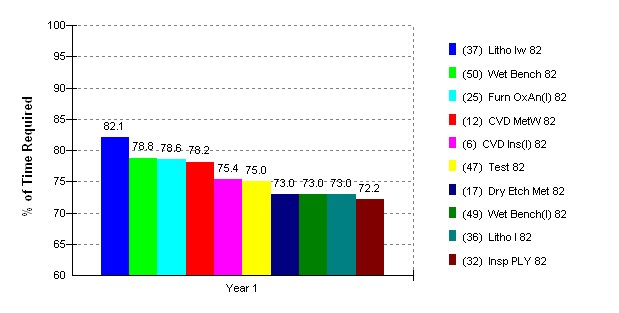

Factory Commander® provides an accurate view of capacity requirements by taking into account product mix changes over time, shared resources, both equipment and staffing, while allowing the user to select the appropriate analysis time frame. Factory Commander® integrates both short-term (week, month, and quarter) and long-term (annual) planning horizons. By allowing facilities that include multiple products and process routings, rework loops, multiple subassembly mergers, and product transformations, Factory Commander® analyzes even the most complex manufacturing environments and yields accurate capacity forecasts.

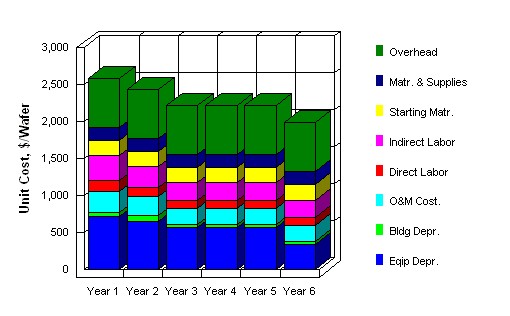

Product Costing

One of the most difficult tasks facing product management is predicting the manufacturing cost of products before they are built. Yet, this information is critical in determining the ultimate profitability of new product introductions before significant investments are made. Equally important is the ability to predict the true cost impact of product and process revisions on existing product lines. Most accounting systems are adequate in hind-sight to determine product costs but lack the ability to be forward-looking in their cost assessments.

Factory Commander® provides a sophisticated bottoms-up Activity Based Cost Management (ABCM) approach to product costing. Based on a high level understanding of process flows, equipment groups, and materials consumption, Factory Commander’s integrated Capital Cost Calculator and Operational Resource Calculator determine total production costs. Specifying the final product demand allows these costs and other overhead items to be allocated for an accurate and straightforward product cost prediction.

Strategic Planning

Constructing an accurate and defensible strategic plan is a challenge for both existing and startup businesses. The common financial analysis approach utilizing spreadsheets to project revenues and expenses can quickly become a nightmare of undocumented assumptions and over simplifications, resulting in doubt and uncertainty by investors, either internal or external.

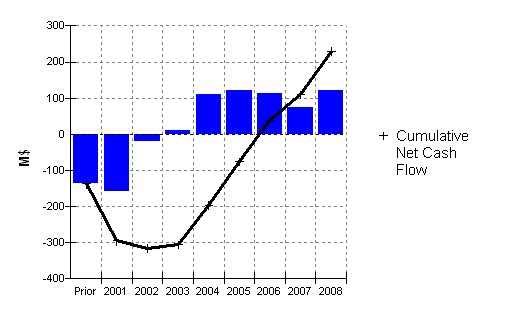

Factory Commander® allows the construction of a virtual representation of most any manufacturing or service based enterprise. By employing a rigorous and repeatable methodology, strategic planners can build in assumptions regarding average selling price and market demand while being provided near real-time views of required resources, cash flow, and return on investment. Factory Commander® allows you to spend more time selling your ideas than defending your mathematics.

Resource Planning

In today’s just-in-time (JIT) manufacturing environments, resources need to be precisely allocated to meet production demand. Many of these resources have long lead-times and must be planned for well in advance of their consumption. When ramping up existing products or adding new products to the mix, floor space may need to be built, equipment ordered, and staff trained. Missing the mark on any needed resource can bring your manufacturing floor to a stand still or miss a critical market window.

Factory Commander® is an ideal tool for planning future resource requirements. Taking into account production demand, Factory Commander® can calculate equipment requirements and their associated floor space, materials consumption, and operating and support labor. This approach not only tracks costs but also resource quantities to better guide the procurement process. Factory Commander® helps you understand the impacts your supply chain has on lean manufacturing and allows you to evaluate the risks in meeting customer commitments.

Product Positioning

Most markets are well served with multiple suppliers that can meet the technical needs of the end consumer. This fact has led most sophisticated buyers to include financial metrics as part of their procurement processes in an attempt to further differentiate the available choices. In turn, savvy marketers in the supplier community have incorporated these financial metrics, traditionally, cost of ownership, into their product positioning statements and marketing strategies.

Wright Williams & Kelly’s TWO COOL® cost of ownership (COO) and overall equipment efficiency (OEE) software has been the tool of choice for focused equipment and material analyses. However, the growing trend in supplier consolidation means that more companies are now able to provide factory-wide equipment and material solutions. Factory Commander® is the ideal tool to quantify the impacts of broad-based solutions in terms of client return on investment (ROI), profitability, and cash flow. For suppliers that may not have access to the necessary manufacturing data, WWK offers data sets and consulting services to enable a thorough analysis of market strengths and opportunities.

Factory Commander® is supported by the world’s leading operational modeling software and services provider, Wright Williams & Kelly, Inc. Whether you need a software tool or a staff of on-site manufacturing experts, we provide the most cost effective solutions to your business needs.

Call today for more information from Wright Williams & Kelly, Inc. Providing software solutions for productivity measurement and enhancement since 1991.

The following are images taken directly from the Factory Commander® application:

Product Data

General Building Data

Process Step List

Cumulative Annual Cash Flow

Equipment Manufacturing Utilization

Unit Cost by Category (wafer fab)