“Cost of ownership analyses helped us to identify optimal preventative maintenance schedules, resulting in annual savings of $20 million worldwide…”

“Cost of ownership is one of the key factors in our decision matrix. Cost reductions and avoidances greater than $2 million for a single purchase have been documented. Similar cost savings are achievable for upgrades, process changes, and materials changes.”

“Cost of ownership software tools help us to effectively manage our multi-billion-dollar capital asset portfolio.”

These are just a few of the public comments that have been made by Fortune 500 firms regarding the value that TWO COOL® cost of ownership (COO) and overall equipment efficiency (OEE) software has brought to their organizations.

Over the past 30 years, cost of ownership has migrated from an evangelical topic at a select few firms to a highly integrated part of corporate cultures. The driving force that propelled COO into the lime light was the severe disadvantage U.S. manufacturers faced during the 1980’s in their cost of capital. They needed a tool to help them employ their higher cost assets more efficiently. COO proved itself successful and has since been adopted by thousands of manufacturers and suppliers regardless of geographic location.

COO is an implementation of Activity-Based Costing (ABC) that helps in understanding all costs associated with a decision. It improves decisions by relating costs to the products, processes, and services the drive that cost. Without such a linkage, it is difficult for organizations to understand the full impact of their decisions on their operating cost structure. With this linkage, COO provides a consistent data-driven method for arriving at important strategic and operational decisions.

Cost of ownership provides an objective analysis method for evaluating potential solutions. First, it provides a clear estimate of the life-cycle cost. The analysis highlights details that might be overlooked, thus reducing decision risk. COO can also evaluate process and design decisions. Finally, COO provides a communication platform between suppliers and their customers. They are able to speak the same language, comparing similar data and costs by using the same analysis methods. Both suppliers and manufacturers can work from verifiable data to support a purchase or implementation plan.

Developing a COO analysis strategy and reengineering business processes identifies opportunities for using COO results to support management decisions. While the perspectives may differ for the manufacturer and their suppliers, both can benefit greatly from using COO analyses. The supplier who provides the most value will ultimately win in the marketplace. The following questions identify some business decision opportunities for applying COO analyses:

- Which supplier provides the most cost-effective equipment or consumable?

- Should we purchase higher capacity equipment to support future production?

- What is the impact of a change in materials at a process step?

- What is the impact of a component change or upgrade in process equipment?

- Does the equipment upgrade provide a positive return on investment?

- Which yield improvement project has the highest overall value?

- What is the impact of process parameter changes?

- What is the impact of changes to equipment operating conditions?

- What are the costs of idle time, down time, and setup time?

- Should we replace existing equipment with new equipment?

Cost of ownership can be applied to many different situations involving equipment, processes, and materials. The benefit of these analyses is applicable to both suppliers and manufacturers. The areas typically examined from a COO perspective are:

- Product benchmarking

- Competitive analysis

- Materials, components, and subsystem impacts

- Project prioritization

- Technology evaluation and manufacturing approach

- Process and manufacturing optimization

- New factory planning

- Product positioning

In the end, COO provides a highly leveraged value to both the supplier and end use communities by tying their technical, operational, and strategic decisions to the bottom line.

The ability to effectively identify cost drivers and manage cost reductions is a competitive advantage. TWO COOL® is the only comprehensive, Cloud-based COO and OEE analysis software that delivers on the promise of bottom line performance. Whether you need to know the cost impact of capital equipment purchases, alternative processes, or OEE improvements, TWO COOL® is THE choice.

Has TWO COOL® helped our customers? Examine the list of benefits that our customers developed for us, then ask yourself, can I really afford not to use TWO COOL®?

TWO COOL® benefits:

- Improves cash flow through capital expenditure avoidance

- Supports “Green” initiatives by analyzing disposal/reprocessing alternatives

- Quantifies material usage reduction costs

- Drives product cost reductions

- Locates opportunities for process step cost reductions

- Reduces operating costs

- Helps rank projects by return on investment (ROI)

- Saves money

- Helps technical staff to understand business implications of decisions

- Determines where time and money should be spent

- Helps management and line staff communicate more effectively

- Helps suppliers and customers communicate more effectively

- Helps finance and technical personnel communicate more effectively

- Makes the decision process more objective

- Works in both new and existing factories

- Supports both large and small expenditure decisions

- Works on wide range of technologies

- Easy to learn

- Used by most leading suppliers and manufacturers

- Globally supported

- Reduces data collection through compliance to existing SEMI® Standards

- Shares data with other operational models

- Works in Windows and Macintosh environments, no special hardware or software required

- Saves you money

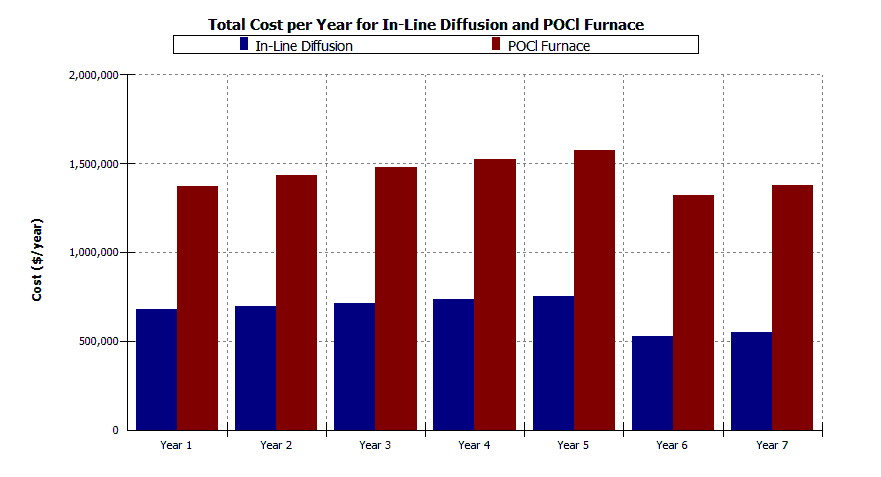

Compare process options to determine the lowest cost solution

Join the growing list of companies that are achieving multi-million-dollar savings. TWO COOL® is the COO and OEE software standard for leading IC, photovoltaics (PV), solid state lighting/light emitting diodes (SSL/LED), nanotechnology, micro electro-mechanical systems (MEMS), thin film record heads, magnetic media, flat panel displays (FPD), and healthcare organizations as well as equipment and material suppliers. When you need to evaluate a supplier or exchange data with your customer, TWO COOL® provides a common language.

TWO COOL® is supported by the world’s leading operational modeling software and services provider, Wright Williams & Kelly, Inc. Whether you need a software solution or a staff of on-site manufacturing experts, we provide the most cost-effective approach to solving your business challenges.

From COO and OEE to full factory analysis, only Wright Williams & Kelly, Inc. offers a full range of solutions. Start increasing your profits today. We’ll make sure you measure up.

Call today for more information from Wright Williams & Kelly, Inc. Providing business solutions for productivity and cost management since 1991.